“The revolutionary development in ground reinforcement”

GRB is a new and revolutionary development in ground reinforcement, with its tough, flexible and easy install features, it makes it the ideal professional choice for a wide range of construction projects.

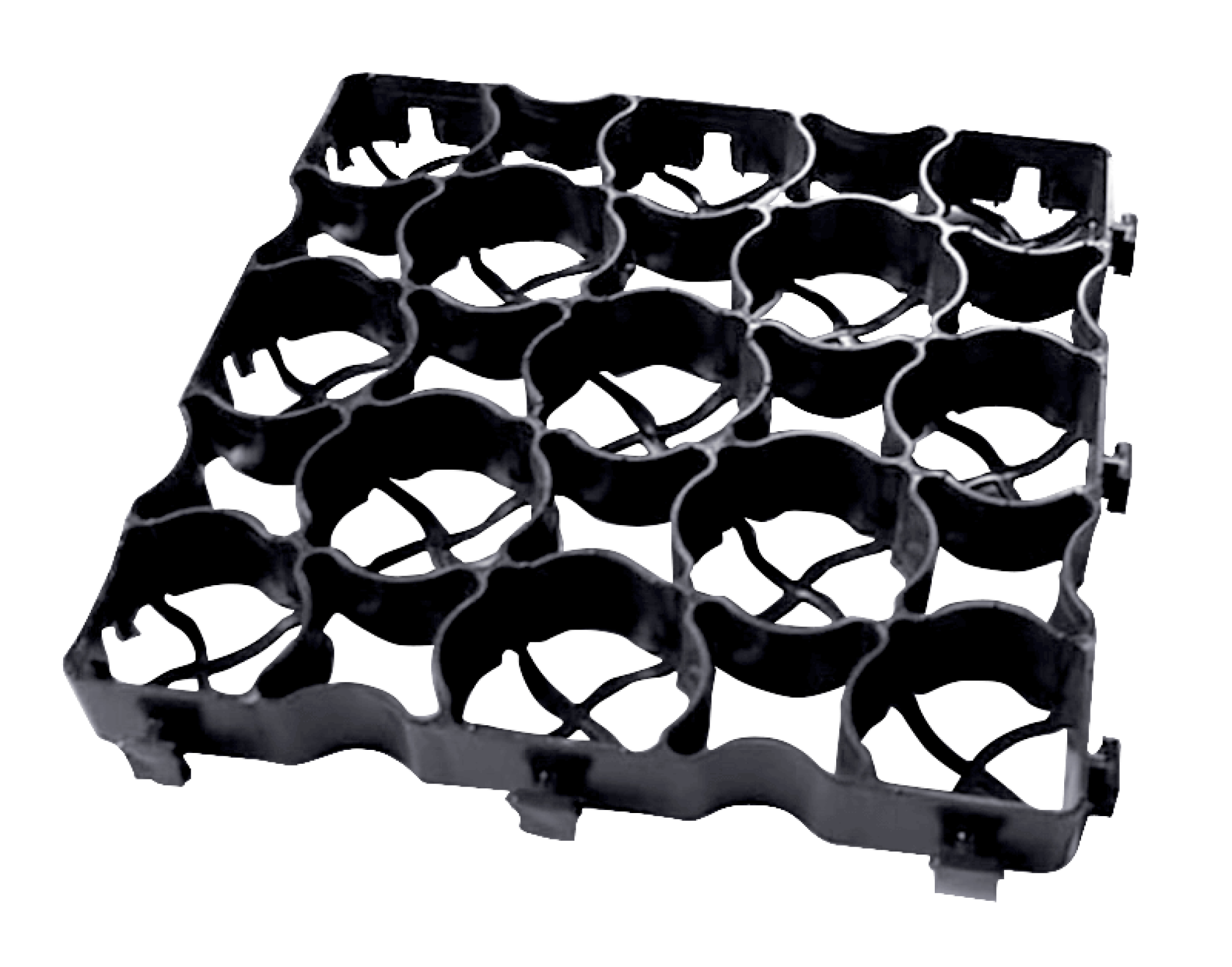

Manufactured from 100% recycled material, GRB is the most environmental and sustainable solution of choice in the prevention of ground erosion. The honeycomb style tiles provide an interlocking system that can be laid at ground surface level, and then either filled with stone, gravel or earth and it is also able to be seeded.

If you are looking to design and create the ultimate, hassle-free driveway, GRB is optimal as it prevents gravel migration and maintain a smooth drive, resulting in a maintenance free area that also has a high aesthetic and street appeal. These qualities also make it the ideal solution for green car parks and other construction projects.

GRB comes with a range of benefits, including:

Quick and easy install, reducing on site costs (up to 100m2 per person per hour)

Lightweight

Proven connection system

Surface reinforcement with natural drainage

Minimal maintenance

Non-slip and crack proof

Weatherproof and environmentally friendly

Frost and UV resistant

Cut to size

Dimensionally stable

Prevents gravel migration

Sustainable

High strength (up to 250t/m²)

Up to 16 tonne axle-load

Low transport and handling costs

Suitable applications include:

Construction sites

Green car parking areas

Private lanes and access roads (inc. emergency access)

Pathways and driveways

Landscapes

Equestrian and livestock facilities

Embankment stabilisation

Golf courses

Green roof and rooftop gardens

River and road embankment

Private airfields

Building site crossovers

Residential driveways

Emergency access routes

Helicopter landing pads

Cycle routes

Installation Instructions

The following instructions are intended only as a guide in general. The same preparation procedures used for traditional paving solutions as used in the construction of footpaths, driveways and access routes should be adopted.

These guidelines assume that a sub-base is to be used beneath the paving system.

1. The area to be protected should be marked out and excavated to the following depths depending upon the final use. Remember to add the depth of the GRB to the figures quoted if the GRB is to finish flush to the surface.

| Project | Typical Depth |

|---|---|

| Patios, Garden Paths | 75 - 100mm |

| Driveways, Public Footpaths | 75 - 100mm |

| Heavy Uses | 150 - 225mm |

| Highways | 150mm+ |

2. Once the full area has been excavated, the sub-base can be installed. Compact the full area to be as level as possible using either a vibrating plate or for larger areas a vibrating roller

3. A thin 40mm layer of sharp sand/soil mix should be laid over the sub-base to level out any imperfections or hollows in the surface of the sub-base. If the area is to be grassed, this mix will provide a suitable substrate for grass root survival and growth.

4. Once the area is level the GRB can be interlocked and laid. The GRB is delivered and any GRB's that need to be cut should be measured and cut before installation where possible leaving full, complete cells along the outer edge.

5. The area can then be backfilled with the medium to be used. If using gravel, we recommend the use of 10mm or less as this will ensure better filling of the cells. If the area is to be grassed, we recommend using a 70/30 root zone mixture as this will prevent the hard compaction of the cells which could be associated with just using topsoil which would limit grass growth. Initially fill to about 10mm below the top surface of each grid as this will protect the grass in its initial growing phase. The whole area can then be seeded and watered.

6. An optional weed suppressant membrane can be used on top of the sub-base before applying the sharp sand as this will prevent weed growth but will allow for natural drainage of rain water to the ground below.

* Please note that as with all forms or paving products it is essential that the edges of the GRB are laid flush to avoid creating any tripping points. This is the responsibility of the installer and Green-stay accepts no responsibility for injuries caused as a result of in-proper laying.